Class 101 mold is built for extremely high production. It is made with the highest quality materials, and, therefore, is the most expensive class of mold. Class 101 mold must go through 1 million or more cycles, and the base must reach a minimum hardness of 28 R/C. Molding surfaces must be at least 48 R/C. Cavities, cores and slide cores must include temperature control measure whenever possible. Cooling efficiency is affected by corrosion as the mold ages; so non-corrosive materials are recommended. A guided ejection system must be used.

- Engineering

- Foreign Tooling

- 3D Printing Services

- Domestic Mold Building

- In house Tool Fabrication

Engineering & Tooling Experience To Meet Your Plastic Molding Needs

“The Total Solution Provider”

Capabilities:

- In House Engineering & Design

- Product Development

- Design for Manufacturability

- Material Selection

- Rapid Prototyping

- FDM

- SLA

- Castings

- Prototype Tooling

- Production Tooling

- Tool Design

- Tool Building (USA & China)

- Full ISIR Submissions

- Machining

- Metal Castings

- Metal Stampings

- Full Production Facility

- In House Engineering & Design

- 30 to 1,500 tons

- Over Molding

- Insert Molding

- Value Added Services

- Pad Printing

- Heat Staking

- Ultrasonic Welding

- Assembly

- Packaging

- Test Fixturing

- Automated Assembly

- Painting

- Plating

- Shielding

- Warehousing

- Distribution

Materials:

File Formats:

Quality:

Contact:

Todd Holloway

Richard C. Remmy

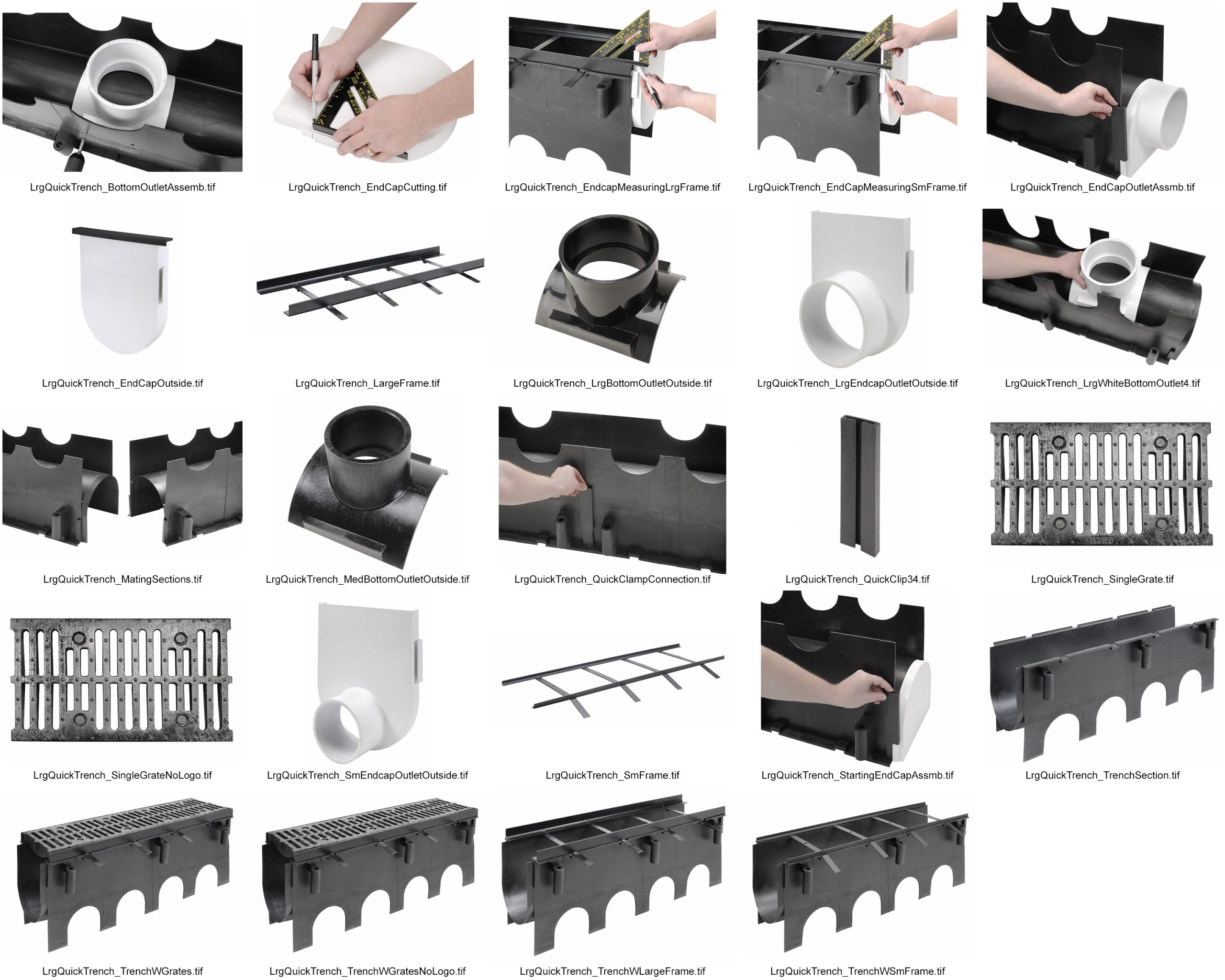

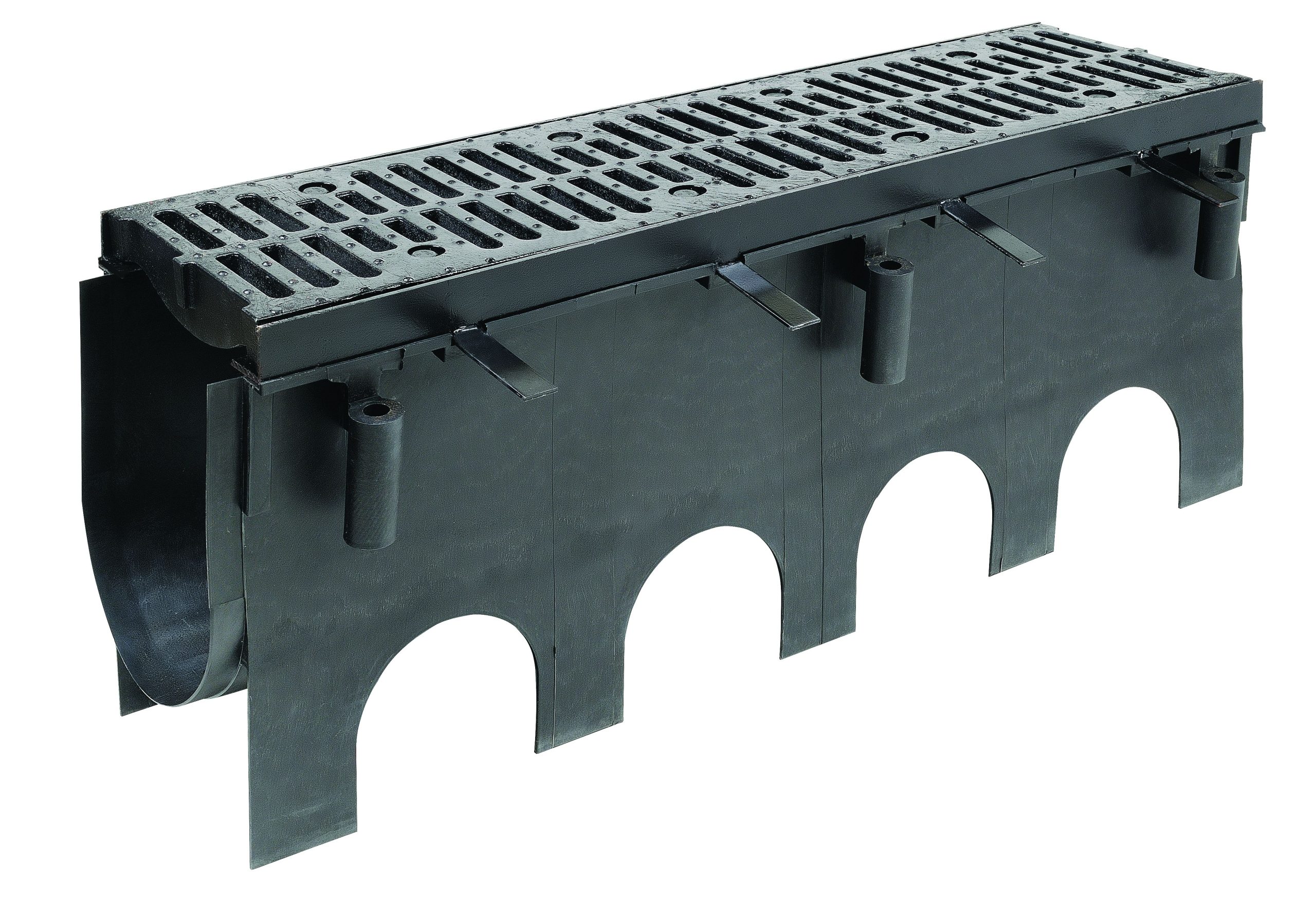

Injection Molding That Gives You A Competitive Edge

- ISO 9001 Certified

- Horizontal Injection Molding from 40- to 1500 ton Clamp Capacity

- Precision and Repeatability to Achieve Critical Dimensional Requirements

Foreign Tooling

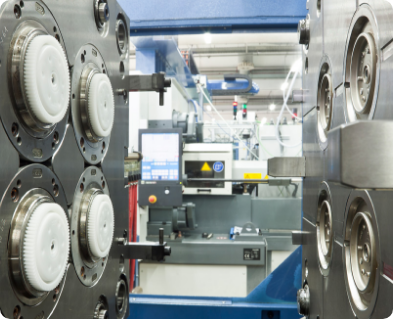

Our Tooling Capabilities range from 80 Ton to 1,500 Ton . All molds are are ungrated, cleaned, and re-sampled in our manufacturing facility to ensure Quality and proper Mold prior to final delivery or in house production.

3D Printing Services

Domestic Mold Building

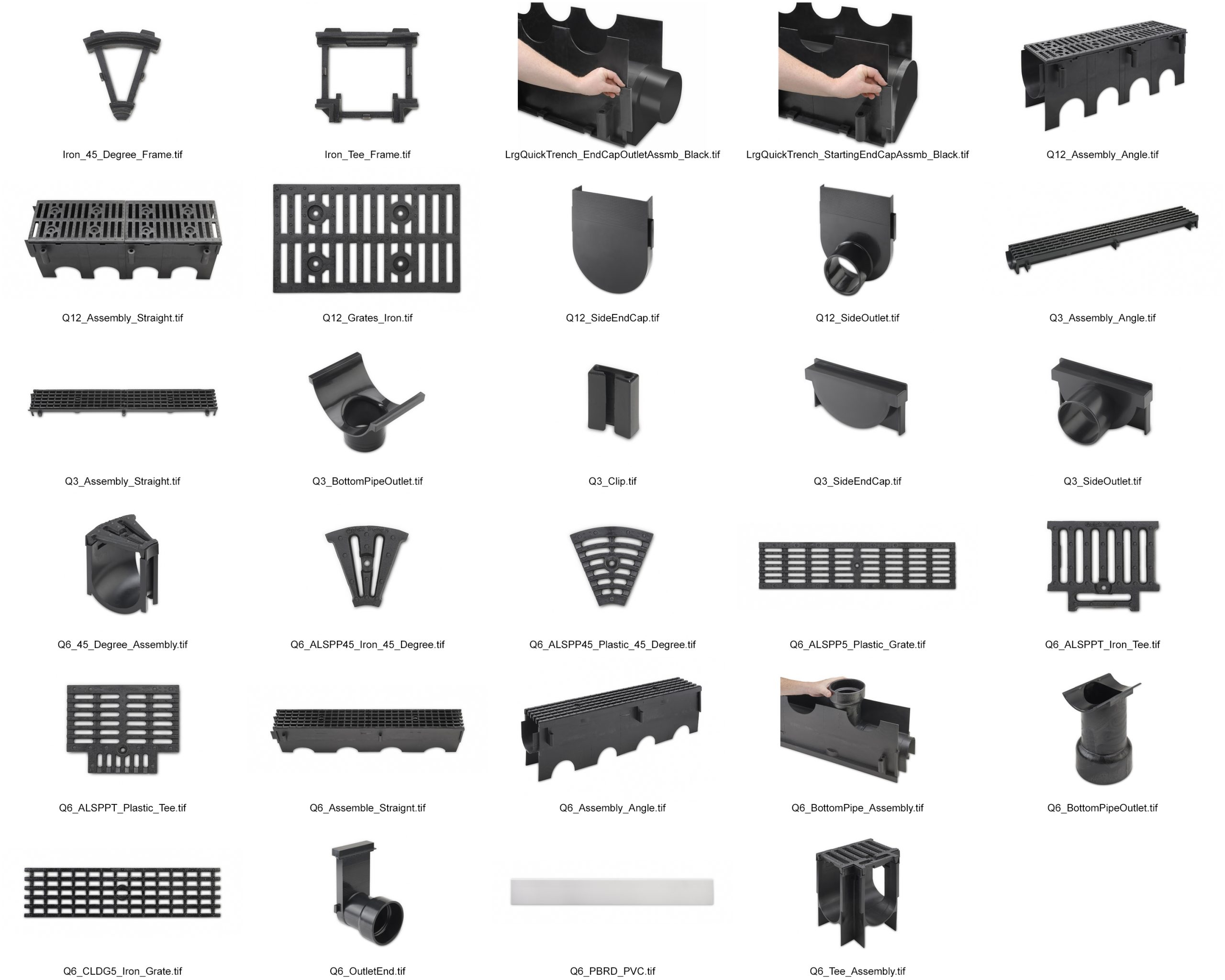

MOLD DESIGN AND MOLD BUILDING FOR LONGEVITY AND PERFORMANCE

- High Cavitation molds

- Automatic unscrewing molds

- Hot Manifold molds

- Stack molds

- Over molds

- Insert molds

- Prototype molds

- MUD molds

- Family molds

MOLD TRIALS AND QUALIFICATION

MOLD TRANFER PROGRAMS

MOLD MAINTENCE PROGRAMS

OVERSEAS MOLD BUILDING AND TOOLING

In house Tool Fabrication

We have experience in medical injection molding, Class VI-compliant, high-performance materials and international trade. We understand that many healthcare product manufacturers do not want production handled out side of the U.S. for a number of reasons–Rigid FDA regulations, material contamination, the exposure of their intellectual property are all concerns of many healthcare companies.

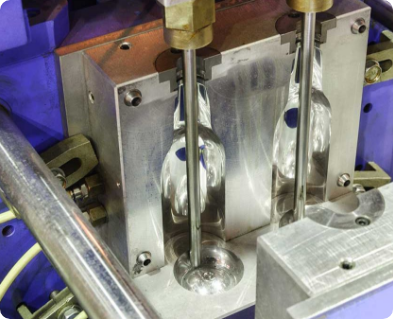

SPI SPE Classification

Class 101 Mold

Class 102 Mold

Class 102 mold is a medium- to high-production mold. It is good for abrasive materials and/or parts that require a close tolerance. This mold is of high quality. Class 102 mold must go through fewer than 1 million cycles, and the base must reach a minimum hardness of 28 R/C. Like Class 101 molding surfaces, Class 102 molding surfaces must be at least 48 R/C. Temperature control measures are used in all cavities, cores and slide cores whenever possible. Guided ejection, slide wear plates, corrosive resistance and plated cavities may not be required.

Class 103 Mold

Class 103 mold is a medium-production mold. It is a popular mold and is in a medium price range. It must go through fewer than 500,000 cycles, and the mold base must have a hardness of at least eight R/C. The cores and cavity must meet a minimum hardness of 28 R/C. Any extra factors, such as guided ejection and corrosive resistant materials, are optional.

Class 104 Mold

Class 104 mold is is a low-production mold. It is used for limited production, primarily with non-abrasive materials. It has a low to moderate price range. Class 104 mold must go through fewer than 100,000 cycles. The mold base can be mild steel or aluminum. Cavities can be made of aluminum, mild steel or any other material that is agreed upon by the manufacturer and the customer.

Class 105 Mold

Class 105 mold is for use only in prototyping. The mold is constructed as inexpensively as possible in a very limited amount. Class 105 mold should not exceed 500 cycles. This mold may be made of cast metal, epoxy or any other material offering sufficient strength for prototyping purposes.

You're In Good Hands

Need a Quick Quote?

Use our quick quote form to get an estimate for your next project. There’s absolutely no cost or obligation..

© Copyright 2024 Lighthouse Industries All Rights Reserved.