30,000+

Projects Delivered

25+ YEARS

Experience

TRUSTED BY

1000+

OUR MISSION

Deliver quality products on-time to our customers.

ABOUT US

Welcome to

Lighthouse Industries

Total Plastic Solution Provider

We are ISO 9001-20015 registered.

Our Achievements

thumb

blade

Development of thumb blade.

Direct Drive

Coupling guards

Development of Falk Direct Drive

Coupling guards.

Flip Fold

Shirt Folder.

Development of Flip Fold Shirt Folder.

single-piece

injection mold

Development of first single-piece injection mold Brachytherapy template for treating prostate cancer.

UpArmored Humvee

program

Joint development of HVAC housing for AM General’s UpArmored Humvee program.

WHY CHOOSE US

Technical

Expertise and

High Accreditations

A Winning Combination

Universal Quality Plan ensures disciplined operation

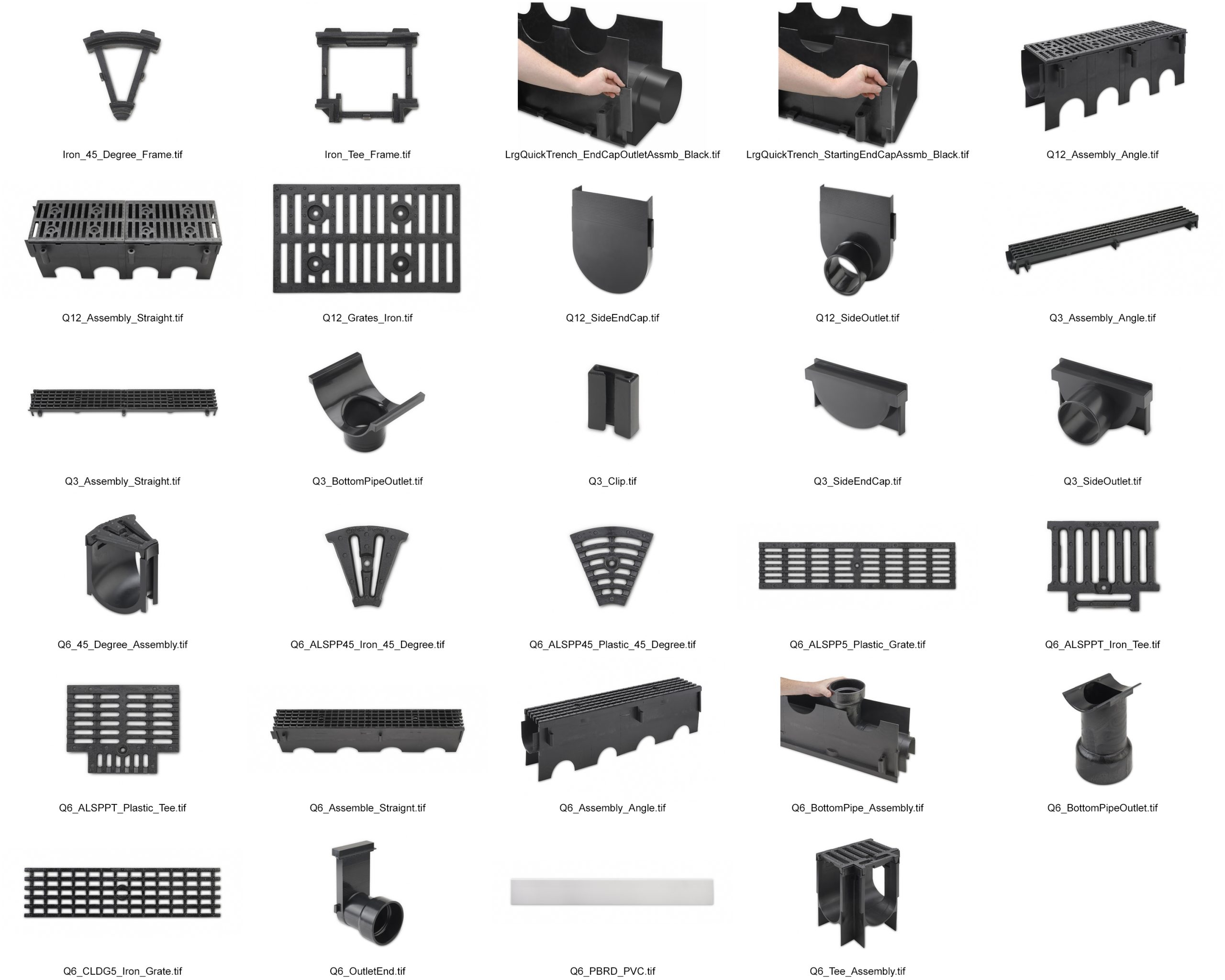

ENGINNERING

3d printing

Foreign tooling

Domesting mold building

Universal Quality Plan Ensures Disciplined Operation

At Lighthouse Industries, we implement a Universal Quality Plan for every assignment, large or small. Team members review and sign off on each phase of operations. Finished products are inspected and tested throughout the manufacturing process, following all applicable inspection and test procedures. Material lot data sheets, process records, and actual part samples are retained for a minimum of three years.

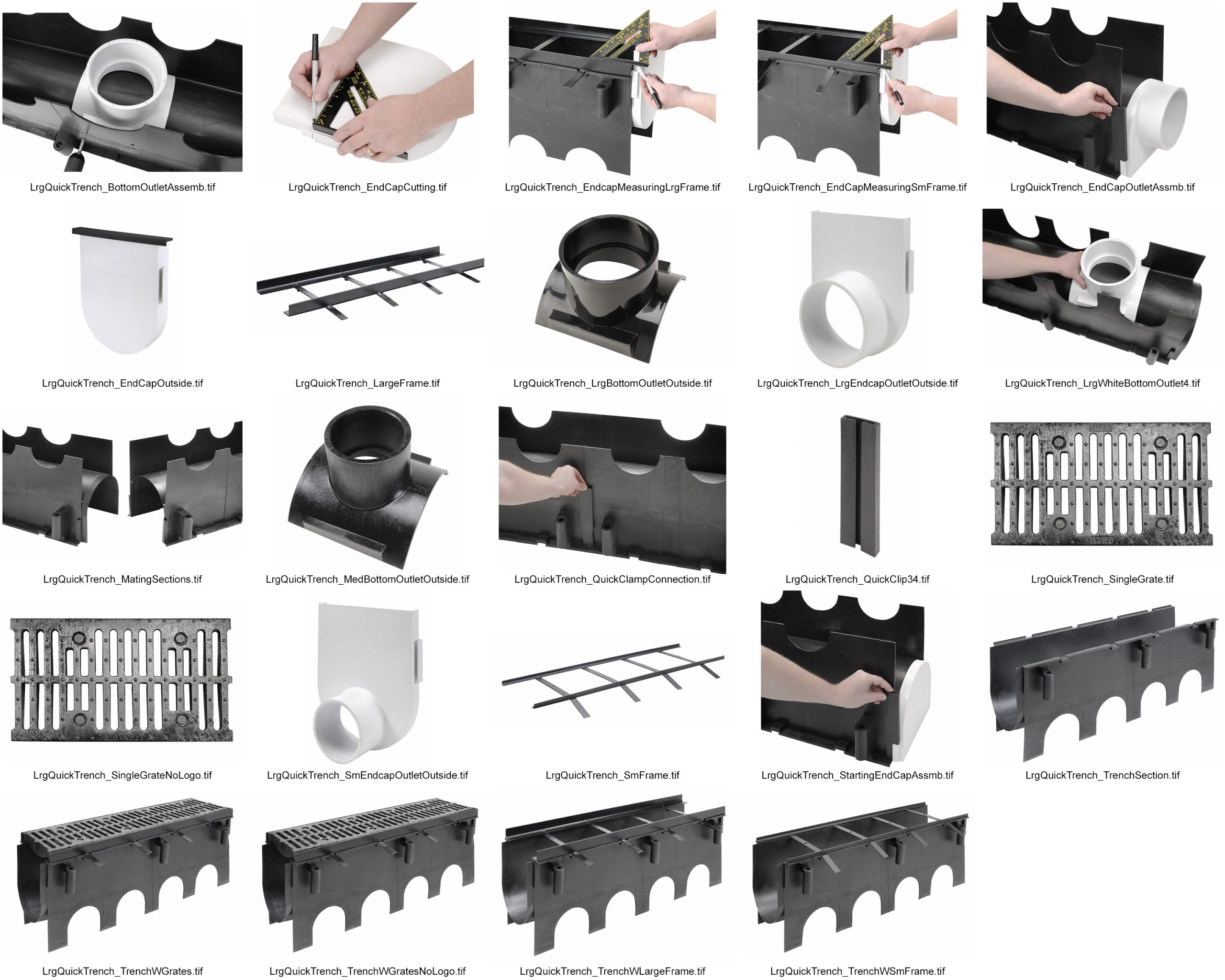

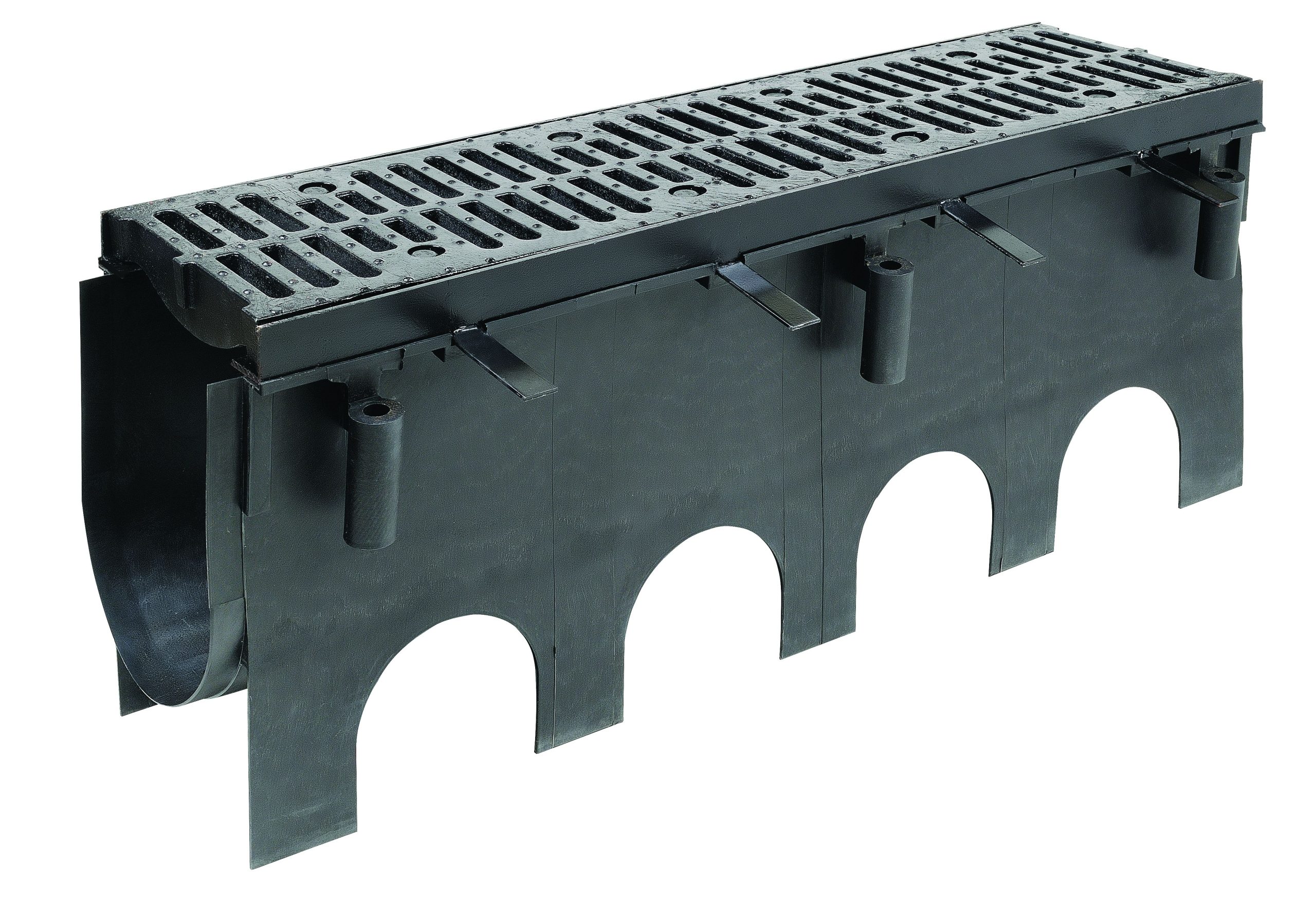

The Right Size And System to Exceed Expectations

Our press capacity ranges from 30 to 1,500 tons, supported by auxiliary equipment including mold temp controllers, chillers, desiccant dryers, hot drop controllers, core pull, air assist and more. We utilize various in-process molding systems and practices such as scientific molding, process monitoring, automatic shut down and alarming, as well as pressure transducer control and monitoring.

Quality Injection Molding Is Just The Beginning

You're In Good Hands

Need a Quick Quote?

Use our quick quote form to get an estimate for your next project. There’s absolutely no cost or obligation..

© Copyright 2024 Lighthouse Industries All Rights Reserved.